There are a lot of features to consider in a hub.

Some are necessary for compatibility, like whether it’s designed for rim or disc brakes. Others are more personal: do you prefer less drag or longer-lasting bearings? light weight or durability? We’re here to help sort through it all.

Compatibility

Brake Type

Rim Brake, Centerlock Disc Brake, and ISO Disc Brake

If your bike has rim brakes, you don’t need rotor attachments. (Though it is possible to use a disc brake hub with a rim brake wheel, it is not common. Be careful with axle types and the rear hub spacing if you’re interested in doing this.)

Does your bike have disc brakes? Then you’ll need a hub designed for a rotor. There are two widely-used rotor attachment standards: Centerlock and ISO (also known as 6-Bolt). Centerlock is a proprietary standard designed by Shimano that uses a splined interface and a lockring. ISO is an open standard that uses six bolts to attach the rotor to the hub.

There are Centerlock and ISO rotor options for almost every brake currently available. Deciding between the two is largely based on preference. Centerlock is easier to install, and some of Shimano’s nicer rotors are available only in Centerlock. However, there are more manufacturers making hubs and rotors in ISO.

Note: it is easy to adapt a Centerlock hub to use an ISO rotor, but not the other way around. If you want the most versatile hub, get Centerlock.

Axle Type

QR Skewer vs Thru-Axle

The axle type is defined by the dropouts on your bike frame. The vast majority of rim brake bikes and many disc brake bikes use a quick-release skewer. Thru-axle’s have become the standard with mountain bikes and are also becoming popular with other disc brake wheels. With these, the axle is separate from the hub. It looks like a heavy-duty quick-release skewer that slides through the left dropout, then the hub, and threads into the right dropout.

Front Axle

The vast majority of rim brake hubs and many disc brake hubs use a standard quick-release skewer with a 9x100mm axle built into the hub.

There are four common sizes of front thru-axles: 12x100mm, 15x100mm, 15x110mm (Boost), and 20x110mm.

Rear Axle

Rim brake hubs for most road bikes use a standard quick release skewer with a 10x130mm axle built into the hub. Disc brake bikes, mountain, touring, and cyclocross bikes often use a sightly longer 10x135mm axle.

There are two common sizes of rear thru-axles: 12x142mm and 12x148mm (Boost).

Note: some Specialized frames have a proprietary 12x135mm thru-axle marketed as SCS (Short Chain Stay). If you have an SCS frame, please let us know so we can discuss your current options.

Drivetrain

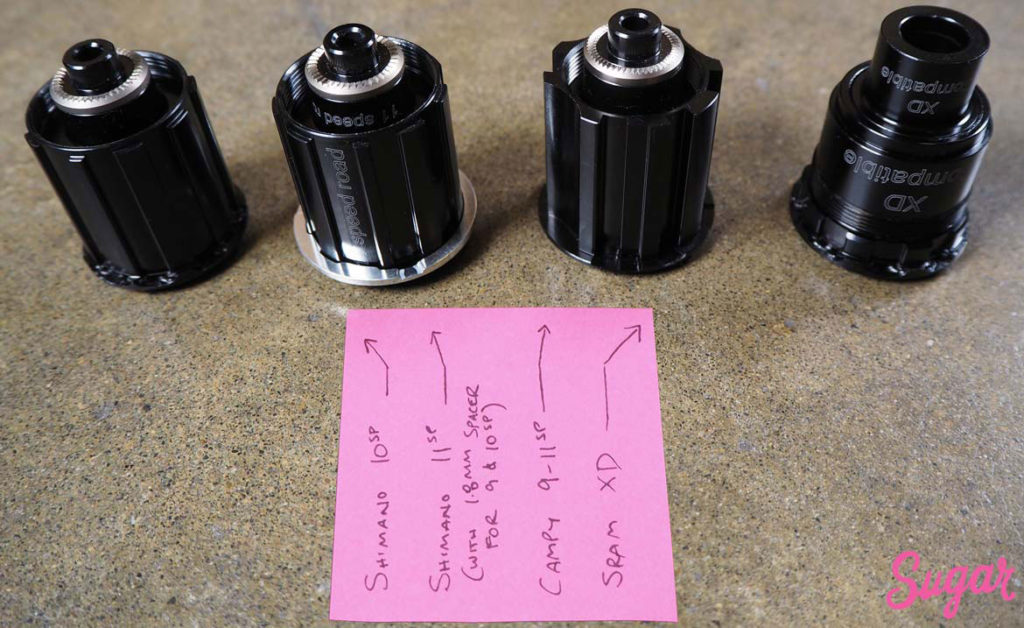

There are four common types of cassette hubs: 10-speed Shimano, 11-speed Shimano, Campagnolo, and Sram XD.

10-Speed Shimano: Shimano’s cassette style is the most common and versatile. It is backward-compatible for cassettes with as few as 7-speeds. It’s also compatible with Sram cassettes. IMPORTANT: 10-speed Shimano hubs are NOT compatible with 11-speed road cassettes. Confusingly, they are compatible with 11-speed Shimano mountain cassettes.

11-Speed Shimano: The same as the 10-speed Shimano, but 1.8mm longer to accommodate an extra cog. Be sure to use this style if you want to use 11-speed Shimano road cassettes.

Campagnolo: Compatible with 9, 10, and 11-speed Campy cassettes.

Sram XD: Uses Sram’s XD driver and one-piece cassettes. IMPORTANT: this is different than a standard Sram cassette. There are no splines, the cassette just threads on to the hub. Contact us if you’re unsure what you have.There are also non-cassette hubs, including freewheel, single speed, fixed, and internally-geared. Please contact us if you are interested in a non-cassette hub. We haven’t added them to our website yet, but we frequently build with them!

Spoke Type

J-Bend vs Straight-Pull

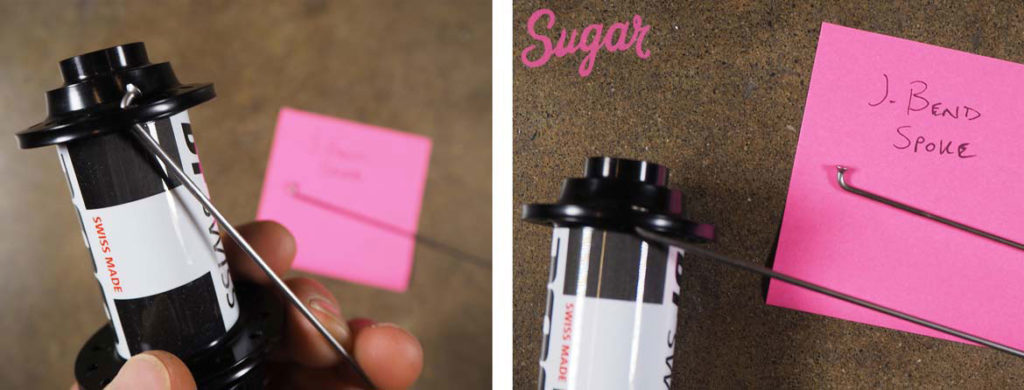

Most hubs use J-Bend spokes. These spokes have a 90 degree bend at the head to allow them to go through a standard hub flange.

Advantages: they’re standard, it’s easy to find J-Bend spokes.

Wheels can be built with these spokes in a variety of lacing patterns.

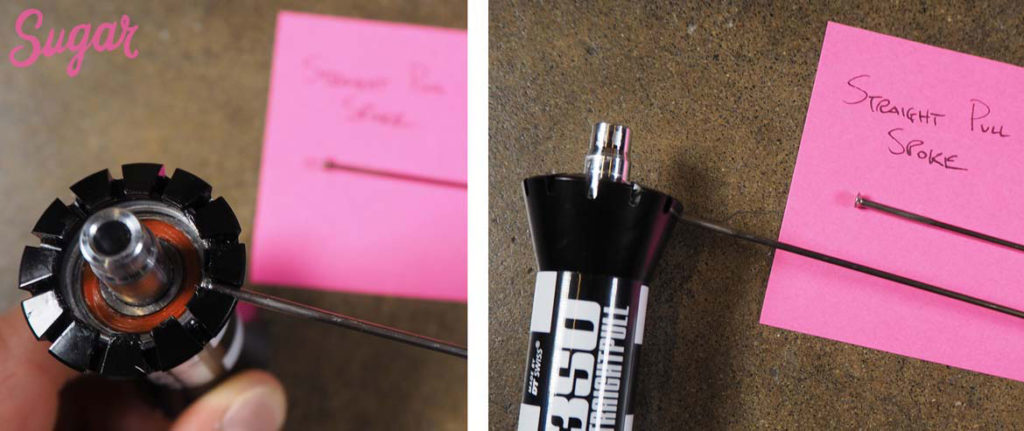

Some hubs are designed to use Straight-Pull spokes. These spokes do not have a bend at the head, they’re just as they sound: straight.

Advantages: The bend is the weakest point in the spoke, eliminating it makes a stronger wheel.

Disadvantages: Only a few hubs are available in this style. It can be difficult to find straight-pull spokes. Without the bend holding them in place, spokes can spin or twist in the wheel. Hubs can only be built with the lacing pattern they were designed for.

Bearing Type

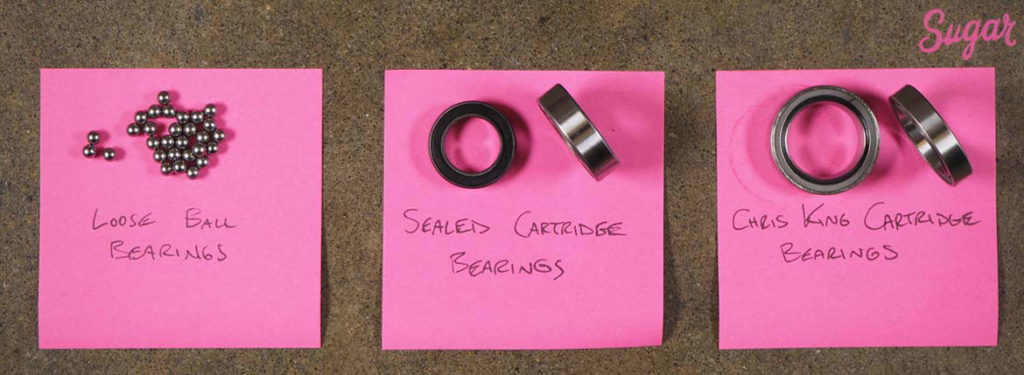

Loose Ball (cup and cone), Sealed Cartridge, and Chris King Cartridge

Loose Ball. Also known as cup and cone, this is the classic standard. Individual ball bearings are in the hub, sandwiched between a cup (typically part of the hub shell) and a cone (typically threaded on to the axle). These hubs require a proper adjustment where they are not overly tight, but also don’t have any play. Shimano is the only company making Loose Ball bearing hubs that we sell. Advantages: It’s very easy to find replacement bearings for these. It’s possible for Loose Ball bearings to have very little drag. Disadvantages: Improper adjustment or neglect can damage the cups and cones in the hub.

Sealed Cartridge. These bearings are the new standard. The ball bearings are sealed inside a ring cartridge. The entire cartridge is pressed into the hub. Advantages: The sealed assembly protects the bearings from moisture and dirt. Because it’s a self-contained cartridge, any damage from neglect is typically limited to the bearing and doesn’t hurt the hub. Typically does not require precise adjustment. There are different styles of cartridges, so it’s possible to replace the stock bearings in your hub with ones that are better sealed or have less drag. Disadvantages: bearing cartridges are more expensive than loose balls and can be more difficult to find. These require specialized tools for extraction and pressing.

Chris King Cartridge. Bearings designed and manufactured by Chris King. These are the bearings used in Chris King hubs, and they are only compatible with Chris King hubs. They look like sealed cartridge bearings, but they are designed to be serviceable, so the seals can be removed and the balls cleaned. Advantages: very high quality and precision made. Serviceable for a long life. Disadvantages: proprietary, so they can be difficult to find and expensive to replace. Removal and installation require Chris King specific tools.

Bearing Material

There are two general components to a bearing: the contact surfaces, called races, and the elements that roll between them, typically balls but sometimes rollers or needles.

Steel. Uses steel balls and races. A great bearing material for most uses. Durable and can be very smooth, depending on the quality of the steel.

Ceramic. Uses ceramic balls and races. Harder and slightly smoother than steel for reduced rolling resistance. Requires less lubrication than steel. Can be long-lasting when used in the right conditions. Will not rust.

Ceramic Hybrid. Uses ceramic balls and steel races. Typically less rolling resistance than full steel and a better price than full ceramic bearings, but not as durable as either. Impacts can imprint the hard ceramic balls into the softer steel races, leaving the bearing feeling notchy or gritty. So avoid those potholes! Expect to replace ceramic hybrid bearings frequently.

Freehub Material

The freehub is the part of the hub that the cassette mounts to. (This doesn’t apply to Sram XD drivers, they’re exclusively made of aluminum.)

Aluminum. The most common for performance hubs, aluminum is light. Aluminum, though, is soft and can become notched from cogs digging into the splines. It’s very important to tighten cassette lockrings to the specified torque on aluminum freehubs. Heavier and more powerful riders should expect to regularly replace aluminum freehubs.

Steel. Also common, steel is very durable. It’s used on most Shimano hubs and a few other heavy duty options like those from Phil Wood and DT Swiss. Much heavier than aluminum. Recommended for heavier and more powerful riders looking for the most durable option.

Titanium. A great application for titanium, it’s much more durable than aluminum and much lighter than steel. It’s available on White Industries and Dura-Ace hubs. Recommended for heavier and more powerful riders.

Engagement System

This is what allows you to freewheel and connects your power to the ground when you start to pedal.

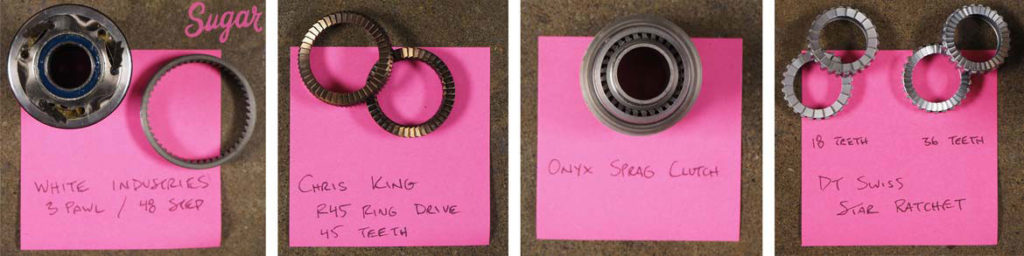

Pawls. The most common style of engagement in a bicycle hub, a few (typically 2-6) small spring-loaded pawls glide against a toothed ring. The teeth are ramped in one direction to allow freewheeling, and they engage with the pawls in the other direction for power transfer. This system has a firm feel with low drag and makes the classic clicking sound.

Ring Drive. Chris King’s proprietary engagement system is similar to DT Swiss’. It uses a pair of toothed rings that engage in one direction and glide past each other in the other. There is more contact area in this system for very strong power transfer, but also more drag while freewheeling.

Sprag Clutch. This system relies on many small sprags that grab the axle when the drivetrain is engaged. There are no teeth used, giving this system a silent, smooth feel with low drag.

Star Ratchet. DT Swiss’ proprietary engagement system is similar to Chris King’s. It uses a pair of toothed rings that engage in one direction and glide past each other in the other. There is more contact area in this system for very strong power transfer, but also more drag while freewheeling.

Engagement Degrees

The measures the distance between points of engagement. The lower number of degrees, the quicker the drivetrain will engage when you start pedaling. Think of it as how far the axle has to spin before the drivetrain engages. Or think of it as the distance between teeth in the engagement system. A ring with 36 teeth, for example, will have 10 degrees of engagement. (For those of you who’ve forgotten geometry: there are 360 degrees in a circle. Divide by 36 teeth to get 10 degrees.) In a Sprag Clutch, the engagement degrees is based on how far the sprags need to move before grabbing the axle.